Modern plant in Russia for the manufacturing of flat glass products and translucent aluminum constructions.

We produce goods from glasswork and translucent aluminium carcasses

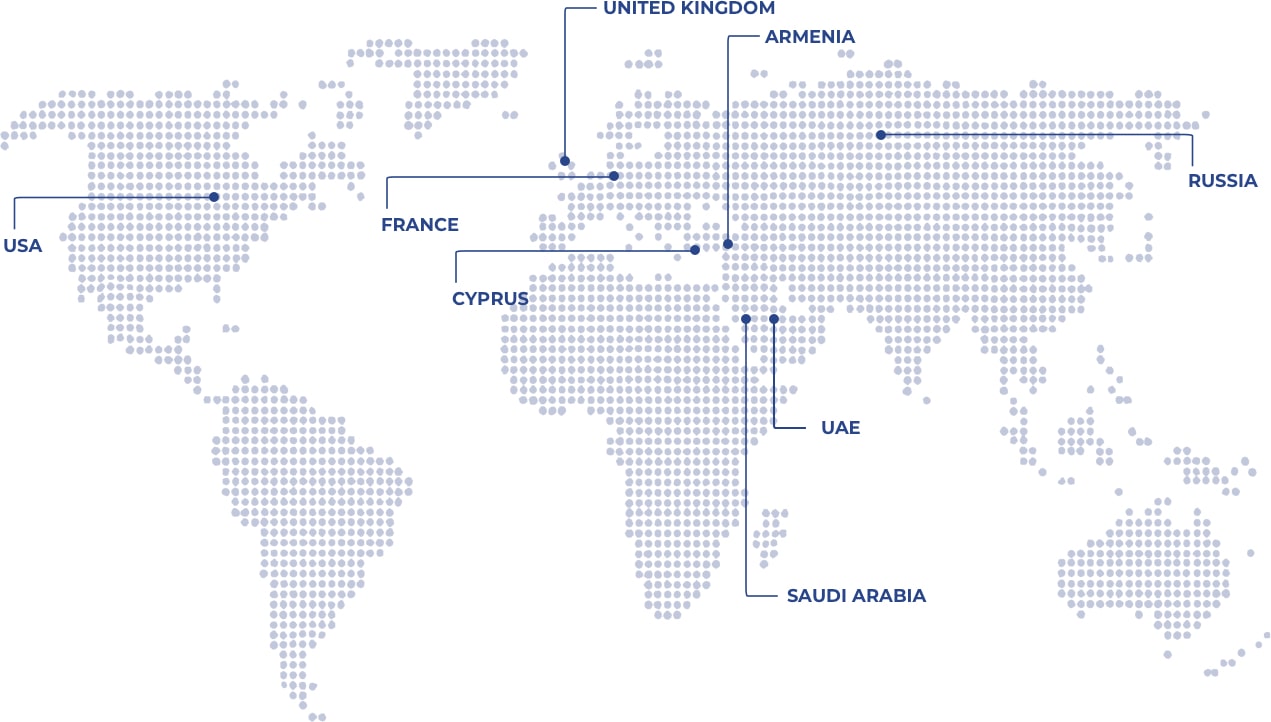

Manufacturing and retail facilities worldwide

Providing unrivalled manufacturing capabilities and services across the globe the manufacturing conglomerate drives business within 40 countries across the Middle East, Africa, Europe and USA.More than 60 years of experience in different projects

Harwal Group was founded in 1938200 000 tons of plastic and 20 000 tons of aluminium and steel

Annual conversion capacityProduct's quality is checked at every stage of manufacturing process

EN / RU